Fly Ash: Pollution and Treatment

By Dharmendra Singh

Fly ash is a by product of power and incineration plants operated either on coal and biomass or municipal solid wastes. It is the world’s 5th largest material resources because of the large amount of ash produced in the world. Fly ash can be classified into several.

categories

- Coal fly ash – Obtained from power plant burning coal.

- Flue Gas – Desulphurization fly ash, that is the byproduct generated by air pollution control equipment in coal fired power plants to reduce the release of SO2.

- Bio-Mass fly ash – Produced in the thermal conversion of biomass.

- Municipal solid wastes incineration (MSWI) fly ash that is the finest residue obtained from scrubber system in a municipal solid waste incineration plant.

Fly ash contains pollutions such as heavy metals and organic compounds. If composion is variable, depending on their origins. For example MSWI fly ash are most problematic ash in terms of contaminant content, coal fly ash contains acidic toxic matter such as lead, arsenic, mercury, calcium etc.

The environment ministry’s expert panel opined that the interface between the water and fly ash at the bottom of a fly ash filled void results in leaking of heavy metals into groundwater system as evident by high levels of trace elements articularly heavy metals in ground water samples collected from sites located close to the ash filled voids. It also reduces the recharging of ground water as it filled mine voids. These voids cannot support tree species due to poor root system. A low velocity winds can result in uprooting of trees.

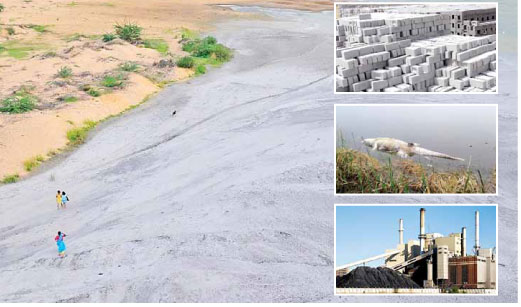

Dumping of fly ash by poorly designed and maintained ash ponds, it is estimated that about a billion times of toxic ash polluting land, air and water. By 2021-22 the thermal power sector are going to produce 300 million tones of fly ash per year.

The Environment Protection Agency (EPA) has found that living near the coal ashdisposal site can increase the risk of cancer and other respiratory diseases. Arsenic contaminated water drinking has increased the risk of Cancer as much as a 1 in 50

Case Study

Singrauli is situated as the north part of MP and its border is SoneBhadra – District (U.P). There are several open cast coalmines and Thermal power plants in the Singrauli – Sonebhadra area spread across MP and UP. The National Green Tibunal (NGT) has confirmed the ever increasing burden of pollution in Singrauli industrial belts. This belt is identified as a “critically polluted area”. Heavy individual activities such as incremental coal mining activities in the region and rapid development of coal based thermal power plants has resulted in acute air and water pollution leading to various health problems among the residents of the locality. About 12,700MW power is generated and nearly 83 million tons is mines per annum. In January 2010, the Comprehensive Environment Pollution Index (CEPI) scores of 81.78 and it is the 9th most critically polluted area of the country. The Supreme Court sought response from the centre and others on a plea seeking directions to restrain thermal power plants in Singrauli (MP) and Sonebhadra (UP), from disposing fly ash in “Rihand Reservoir” and other water bodies. In October 2019, S.C issued notices to the ministry of Heavy Industries, ministry of Water Resources, Environment Ministry and Central Pollution Control Board along with MP & UP state Gov and NTPC’s to submit their replies. The negligent act of power plants more than 35 lakhs metric tons of fly ash entered into the “Rihand Reservoir”. This reservoir is only source of drinking water for the people and the entire water has been contaminated. Another example of fly ash laden water from power plants ESSAR’s Mahan Thermal Power Plant is spilled into villages when mud wall of fly ash duke collapsed. This is really a very serious matter and an action plan is to require for the management of such fly ash.

Treatment of Fly ash

Fly ash is a valuable resource with potential use in several applications like agriculture, synthesis of geolite and geopolymer and ash bricks for building construction. Fly ash is also used as cement manufacturing. Thus fly ash recycling will reduce landfilling disposal raw materials employ, green house gas emission and water consumption. High quality Fly ash improve concrete strength and reduce heat of hydration of concrete but from all these, only 31% of the total fly ash is effectively used for a beneficial purpose in Australia and rest of the fly ash is typically placed into the storage site for future use. There is still a challenge to develop technique to mange high percent of fly ash developed into the bank of rivers. 65% of fly ash produced from Thermal Power Stations is disposed of in landmills and ash ponds. This process prevents the chemical compounds from being leached into the ground water and local Eco System.